Posted by admin on June 11th, 2012 — Posted in Ball Mill

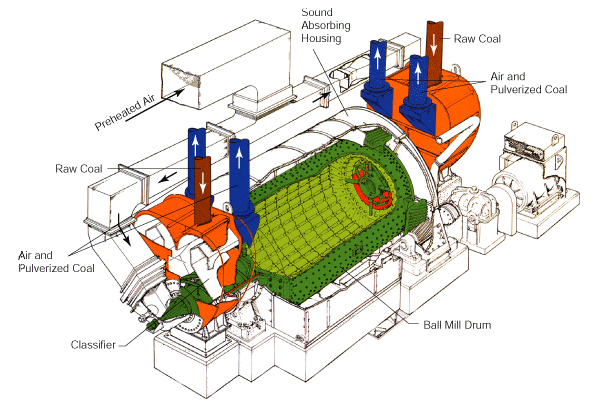

Description of the equipment and how it works:

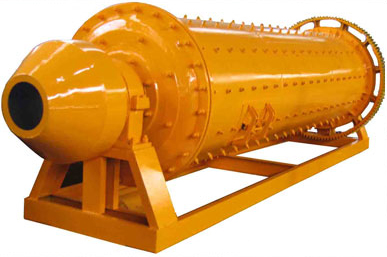

ball mill

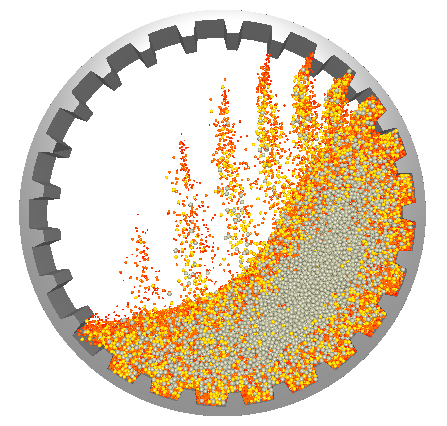

Individuals who have ever been in a processing plant in which hard material are ground into fine powder may have heard of a ball mill, but most people wonder, what is a ball mill? A ball mill is a type of device that is used for grinding and turning the material into very fine powder. They are cylindrical and they are mostly used in mashing paints, ceramic materials, ores and hard chemicals. The ball mill is rotated on an axis that is horizontal and this is how it is able to convert the material into very loose powder.

A ball mill usually has a grinding material which could be stainless steel balls, ceramic balls or even flint pieces. These balls are necessary for the ball milling process because when they grind against another material, this material is crushed into fine powder.

When asking what is a ball mill, it is important to also know how it works. The ball mil is usually operated by a machine, which feeds the materials to be ground through one end, and it is passed through the milling balls and out of the other end as fine loose powder. Most ball mills use balls made of stainless steel because steel can pulverize most materials, though a disadvantage is that steel cannot be used with materials that are flammable or sensitive. In such cases, ceramic and flint balls replace steel in the ball mill.

When asking what is a ball mill, it is important to also know how it works. The ball mil is usually operated by a machine, which feeds the materials to be ground through one end, and it is passed through the milling balls and out of the other end as fine loose powder. Most ball mills use balls made of stainless steel because steel can pulverize most materials, though a disadvantage is that steel cannot be used with materials that are flammable or sensitive. In such cases, ceramic and flint balls replace steel in the ball mill.

Posted by admin on May 31st, 2012 — Posted in Minerall Processing

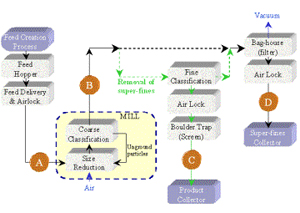

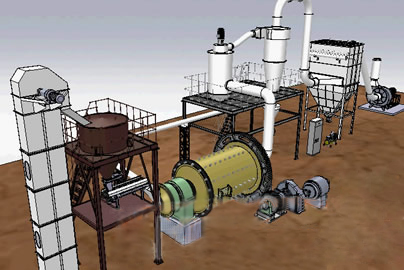

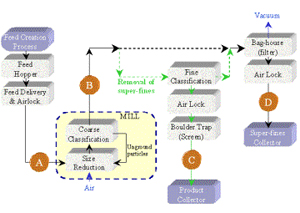

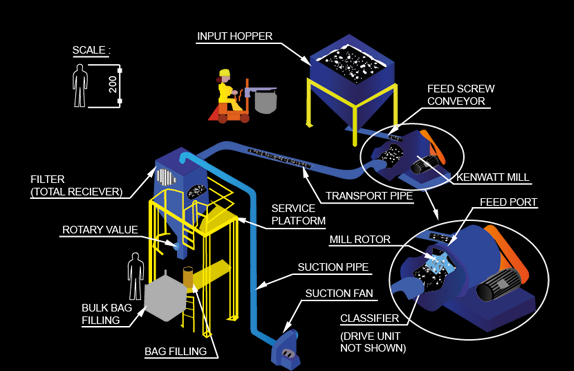

Ball milling processrefers to the process of grinding materials of different kinds into powder using a ball mill. This process is usually undertaken in the building industry, in the chemical industry and in the mining industry. There are two major types of processes which are the dry and the wet processes.

ball milling process

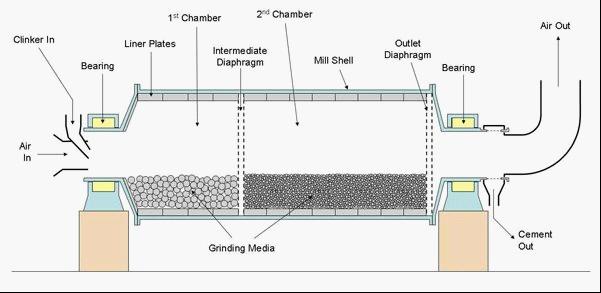

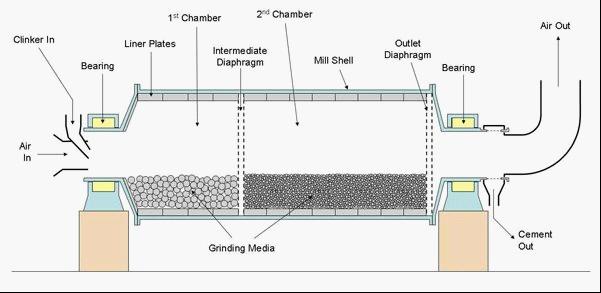

Examples of materials that ground using a ball mill are cement, fire proof material, non-ferrous metals, ceramics, glass, black metal, cement and silicate products. The equipment has a horizontal type as well as tubular running devices with two warehouses. The outside of the machine runs across a gear. The material to be milled enters evenly through the first warehouse of the ball mill along the input hollow axis. There are different types of steel balls and when the body of the barrel rotates, it produces centrifugal force. The steel balls are carried to a certain height and then they fall, thus grinding the material.

After the material has been ground to a coarse powder in the first warehouse, the coarse powder enters the second warehouse where it is reground with the steel balls into finer powder and ultimately, the fine powder is released at the end through the output board and this is what marks the end of the ball milling process.

Ball milling process refers to the process of grinding materials of different kinds into powder using a ball mill. This process is usually undertaken in the building industry, in the chemical industry and in the mining industry. There are two major types of processes which are the dry and the wet processes.

Examples of materials that ground using a ball mill are cement, fire proof material, non-ferrous metals, ceramics, glass, black metal, cement and silicate products. The equipment has a horizontal type as well as tubular running devices with two warehouses. The outside of the machine runs across a gear. The material to be milled enters evenly through the first warehouse of the ball mill along the input hollow axis. There are different types of steel balls and when the body of the barrel rotates, it produces centrifugal force. The steel balls are carried to a certain height and then they fall, thus grinding the material.

After the material has been ground to a coarse powder in the first warehouse, the coarse powder enters the second warehouse where it is reground with the steel balls into finer powder and ultimately, the fine powder is released at the end through the output board and this is what marks the end of the ball milling process.

Posted by admin on May 22nd, 2012 — Posted in mineral milling

Mineral milling is the process of grinding minerals into a fine powder. It is different from the process of granulation or crushing which is about the reduction of the size of a mineral to the size of a grain. Before milling a mineral, it is important to first determine its characteristics which include its hardness, brittleness, toughness, stickiness, melting or softening temperature, structure, abrasiveness, chemical stability, purity, homogeneity, free moisture content and structure.

mineral milling

The hardness of the mineral determines the specialization as well as cost of the type of mill that will be used. Brittleness is the ease with which a material will break. The free moisture content of a mineral should be low in order to ensure that the milling process takes place without any problems while the size and the degree of fineness of the mineral is required in order to know which mill to use.

There are various types of mills that can be used in the milling process including roller mills, hammer mills, pin mills, turbo mills, ball mills and vibrating mills. Each type of mill has different features and it is suitable for milling minerals with specific characteristics. For example, autogenous mills mill minerals that are fairly coarse into products that are relatively fine.

Posted by admin on May 3rd, 2012 — Posted in Minerall Processing

Mineral milling is not an easy task as many people perceive. There is a lot that is required to add up to give required end results and these services are offered by professionals that are well conversant with the milling business. There are things you need to consider if you are looking for good mineral milling services company.

Mineral Milling Services

All over the world there are specific companies that are known over the years of good mining services. Most of these companies have been listed in the mining website and better still they are listed in their own websites. They have all important information that is required to be seen by the client who is looking for the services.

To get good mineral milling services you need to compare many different companies and also looking around for those companies that have had good experiences with such companies. The mineral milling business requires you to get a good company since the mining takes a long period of time.

Mineral Milling Service

Once you have chosen a company you need to take a look at the machinery they intend to use. For one they need to be able to consume a less power and also mill in large volumes. Milling services that are recommended should be able to give you warranty of the machinery they are using and also provide the best engineers to maintain your machinery and also staff that will operate the machines to the required standards.

Posted by admin on April 25th, 2012 — Posted in Minerall Processing

Mining of substances like minerals is usually done on a large scale and from many meters underneath the ground. The material mined are very heavy and brining them up in this status could require a lot of very heavy machines and in most cases they can’t with stand the weight so they spoil fast. Technology has made al this easier by providing milling options and it’s called mineral milling.

Mineral Milling

Mineral milling is whereby grinding machines are used to grind the raw materials to finer forms for easy transport. Also even for easy means for transforming to an end product. This process is reversible to those particles that are not fine enough. Solid matter are ground using string mechanical forces that are used to trench internal forces that are holding the material together and break them. There are other grinding mineral millings that are used to produce manufacturing products.

Mineral milling is mainly done by large companies since it requires a lot of big machineries which are very expensive to purchase as an individual. These machines are usually transported in pieces and then they are reassembled at the plant where they will be used to grind. Each machine has a manual to help determine how each material can be grinded. This is because different rotation power is required to be used. Different mediums are also used to grind different raw materials. All these requires trained personnel to ensure the machines are working and are well maintained.

Posted by admin on April 23rd, 2012 — Posted in Minerall Processing

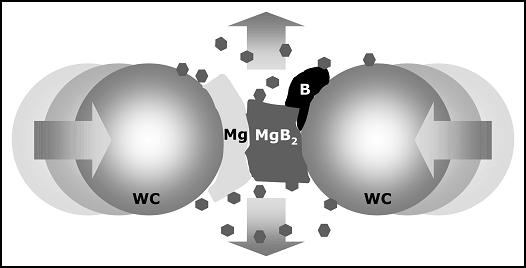

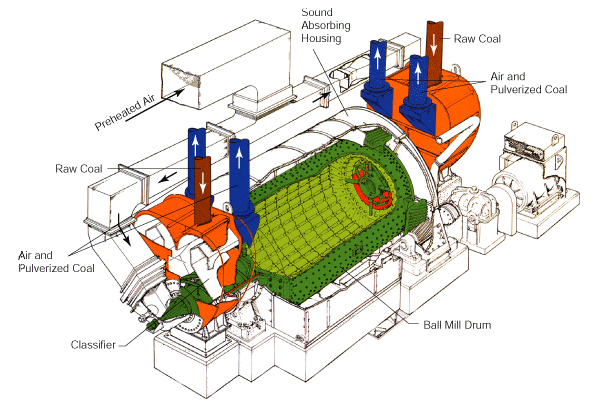

Planetary ball millis a type of cylinder that is used to grind materials into small particles. There are other materials that are ground and there are mediums that are used to make the process successful and complete. These machines are the latest technology that has been modified to use lees power and also give mass production. There are both large machines that rotate on their axis and small ones that sit on drive shafts.

Planetary Ball Mill

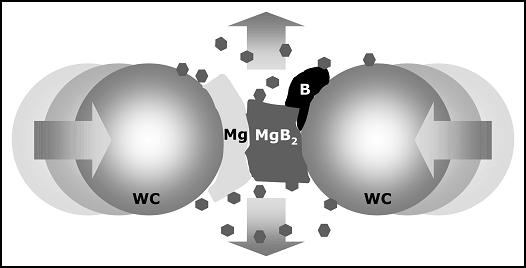

Planetary ball mill consume less space since they are smaller and they are mostly used in laboratories. They grind sample material right down to the smallest particles. They include a grinding jar which can be more than one that is arranged eccentrically on a wheel which moves in a different direction from the grinding jars. Coroilis forces are the rotational movements which are found in the grinding jars.

The speeds that run the balls inside the mills produce an interaction between impact forces and frictional forces. They release high dynamic energy making the products grind to form fine powder as end product. Reaction rate is increased by the operator depending on how fast the product is needed and also the volume. These machines are normally expensive but they are really safe to use in laboratories. Shipping arrangements can be made with the manufacturers to ensure the planetary ball mill gets to you in one piece however you could be forced to foot the extra charges.

Posted by admin on April 20th, 2012 — Posted in Minerall Processing

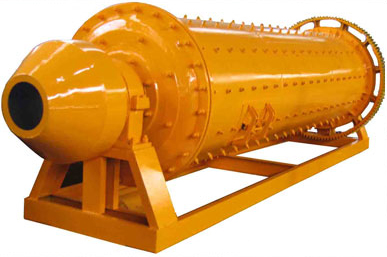

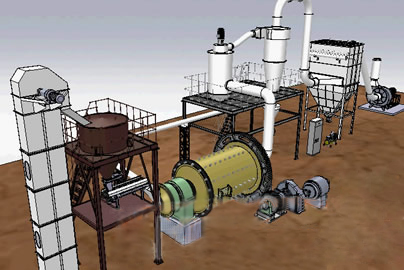

Machinery in most cases is used to manufacture an end product and mineral ball mills are used for the same purpose by grinding. Machines have different mechanism on how they work so that the end product can be achieved. It’s important for any one who intends to buy mining machine to know how mineral ball mills work.

Mineral Ball Mills Work

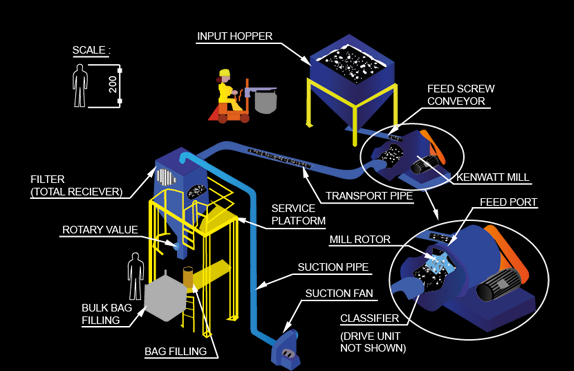

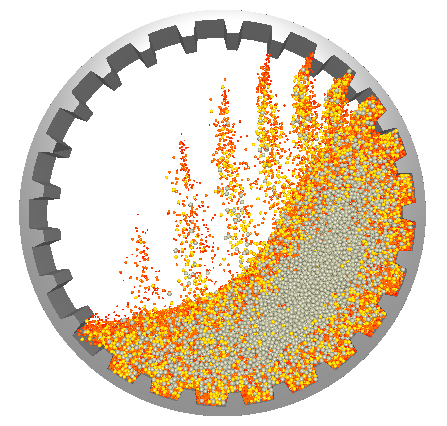

The cylinder either rotating on its axis or using a cylindrical container rotates at a relatively low speed. This is to allow the balls to cascade or move in the mill base and allowing for the grinding of the material to occur. The rotation according to engineers should happen at twenty revolutions per minute which is highly determined by the diameter of the mill. If the diameter is large then the rotation is slower.

A closed system is preferred to operate the mineral ball mills so as to achieve reasonable efficiency. Over size material is usually and continuously re circulated back to be reduced and the discharge from the ball mills are usually classified using screens, cyclones and air classifiers. To grind the materials to finer powder the speed is usually increased especially if the machinery is using electricity and not fuel to power. This is because controlling becomes easy. there are mineral balls that are used to grind cement and these are usually large and they consume a lot of fuel or electricity

Machinery in most cases is used to manufacture an end product and mineral ball mills are used for the same purpose by grinding. Machines have different mechanism on how they work so that the end product can be achieved. It’s important for any one who intends to buy mining machine to know how mineral ball mills work.

The cylinder either rotating on its axis or using a cylindrical container rotates at a relatively low speed. This is to allow the balls to cascade or move in the mill base and allowing for the grinding of the material to occur. The rotation according to engineers should happen at twenty revolutions per minute which is highly determined by the diameter of the mill. If the diameter is large then the rotation is slower.

A closed system is preferred to operate the mineral ball mills so as to achieve reasonable efficiency. Over size material is usually and continuously re circulated back to be reduced and the discharge from the ball mills are usually classified using screens, cyclones and air classifiers. To grind the materials to finer powder the speed is usually increased especially if the machinery is using electricity and not fuel to power. This is because controlling becomes easy. there are mineral balls that are used to grind cement and these are usually large and they consume a lot of fuel or electricity

Posted by admin on April 18th, 2012 — Posted in Minerall Processing

A ball mill mineral machine or a grinder is used in mines to grind material into a fine powder. The grinded materials are in turn used in mineral dressing process such as pyrotechnics, paints and ceramics. It mixes materials like ores and even ceramic raw materials by rotating in a round horizontal axis. The mills are filled half way with the material to be grinded and the grinding medium or product is also put.

There are different sizes of ball mills and the large ones are the ones that rotate on their axis while the smaller ones consisting of a cylindrical container, normally sits on two drive shafts. To transmit the rotary motion using pulley and belts and in different occasion a rock tumbler is also used.

Ball Mill Mineral

A ball mill mineral can be used to grind both wet and dry products and there are two types of ball mills namely over fall type and grate type depending on the different ways they discharge materials. There are also many types of grinding media and there properties are density, size, composition and hardness.

There is ball mill mineral that is commonly used in laboratories and are called planetary bill mill. They are used to grind materials into smallest size while giving a demonstration to students or manufacturing something by professionals.

Posted by admin on April 16th, 2012 — Posted in Mineral Ball MIll

Usually there is a defined market where you can find different machinery depending on the tasks they perform. Bill mall machines are usually used for mining and this means these are real huge machinery by size. Finding a sale store for them could cost you a lot of money since they will occupy a big space. Unless the machinery can be viewed from the go down there should be other places where one can find mineral ball mill sale.

- Mineral Ball Mill Sale

Manufacturing companies have had to adapt to technology to ensure their products awareness reaches to their far customers as well. Today the technology has come as close to our living rooms. This means technology such as the internet and television could easily get you what you are looking for. Internet is a good place to start looking for mineral ball mill sale.

Most manufacturing companies have a website that they use to advertise their mineral bill mall sale. They place the photos of their machineries depending on the different models they manufacture. They have made the work easier for their clients by giving a detailed description of the machine so that you can have the correct information while making your decision. You will find these companies giving out sale of their products at given periods of the year. This means one can save and buy the machine when there is a sale and save a lot of money in the process.

Posted by admin on March 3rd, 2012 — Posted in Ball Mill, Minerall Processing

A ball mill is a machine that is filled with materials and the rotated to grind the material into fine powder. The material that is ground is used in pyrotechnics, ceramics and paint. The main reason behind grinding materials is that increases the rate at which the ground material will react with other materials. If you want to make a quality fine material back at home, you need a ball mill. Note that when using ball mill, it may explode especially if you are using volatile materials. As such, you need to be cautious.

The materials needed for making the ball mill is readily available, you need a motor, container and a roller. Constructing the mill is very simple; just make sure that the container is placed on the roller with two wheels. Then place a copper rod through the container which will be driven by the motor wheel on the right. This simple ball mills how to build guideline can be found on various websites. Note that the mill is dangerous, as such, you need to be cautious as you are using it.

When asking what is a ball mill, it is important to also know how it works. The ball mil is usually operated by a machine, which feeds the materials to be ground through one end, and it is passed through the milling balls and out of the other end as fine loose powder. Most ball mills use balls made of stainless steel because steel can pulverize most materials, though a disadvantage is that steel cannot be used with materials that are flammable or sensitive. In such cases, ceramic and flint balls replace steel in the ball mill.

When asking what is a ball mill, it is important to also know how it works. The ball mil is usually operated by a machine, which feeds the materials to be ground through one end, and it is passed through the milling balls and out of the other end as fine loose powder. Most ball mills use balls made of stainless steel because steel can pulverize most materials, though a disadvantage is that steel cannot be used with materials that are flammable or sensitive. In such cases, ceramic and flint balls replace steel in the ball mill.